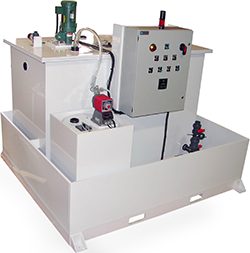

CUSTOM pH ADJUSTMENT SYSTEMS

|

|

|

|

Experienced engineers coordinate your project from design through start-up. We stand firmly behind every system we supply with full service and technical support.

If your process changes, our team of engineers can assist you in making the modifications as needed. Wastech understands the demand of your production schedule and that is why we offer around-the-clock service for our customers.

Wastech is a single-source of responsibility for your application. Our engineers, chemists, and technicians apply their extensive knowledge and experience to design and construct the entire system. This "total-project" concept and our commitment to incorporate the best available materials in the design and fabrication of any job, guarantees that we can provide the best solution for your specific application.

Custom Space Requirements

Wastech can customize pH neutralization systems in many different ways. One of the most common ways we are asked to customize a treatment system is to make it fit within a desired floor space. Some customers either have limited installation space available or a restricted path leading to the installation point, such as a freight elevator, where thoughtful planning is required to make sure the project is a success. We can make use of our capabilities to fabricate rectangular reaction tanks instead of using molded round tanks to save space. We can also use a multi-skid design where normally a single skid would be adequate if it weren’t for that dreaded door leading to the point of installation. We design all of our systems in 3D, which lets us and our customers visualize the end result and pick up on any interferences before the system is built.

Secondary Containment

Secondary Containment

Our standard pH neutralization systems are designed with an adequate level of secondary containment for most applications. Some of our customers request that we take secondary containment to the next level. All of our pH adjustment systems use metering pumps to inject chemistry to neutralize the waste. The discharge lines of the metering pumps have containment tubing at the most probable leak points as part of our standard design. To make the system more secure, we can fabricate polypropylene cabinets around the metering pumps so that if a leak occurs, the chemical cannot spill onto the floor or to any other part of the system. We can also fabricate polypropylene containment around chemical supply piping, pump discharge piping, and any other part of our systems that could possibly leak.

Advanced Automation

Advanced Automation

Wastech pH neutralization systems are designed to be fully automated with little to no need for operator supervision. Most of our custom neutralization systems are PLC controlled. Some facilities have a Building Management System (BMS) where they monitor data from all around the plant. We can provide the communication devices that allow our clients to access whatever data they need to monitor elsewhere.

Even with a fully automated system, there are maintenance tasks required by operating personnel. One task is to clean pH probes to prevent them from fouling and giving erroneous readings. We can eliminate this task by using automatically retractable pH probes that flush themselves with water to keep the probe free from debris, gunk, and whatever else might cling to the probe.

Outdoor/Remote Location Design

Outdoor installation is required by customers who simply don’t have space available for a new waste treatment system. Depending on the environment, there are a lot of factors that go into designing a system for outdoor installation. Our engineering team has years of experience with outdoor designs, and we can provide a solution for any application. Some systems can be weatherized by simply putting an awning over the system. Others will be exposed to extreme temperature conditions and require heated tanks and pipe tracing, heated pump enclosures, or air conditioners for control panels.

Some treatment systems will be installed in remote locations with minimal utilities available. One example is a system that was to be installed in the desert in the middle east and required chilled water for the treatment process. A packaged water chiller was provided as part of the skid because a city water supply was not available. Another example is a system that was installed in a modified shipping container so that it could be moved from jobsite to jobsite. Whatever the challenge, Wastech’s design team can provide a solution.

Have questions about ordering a custom pH Adjustment System?

One of Wastech’s application engineers will discuss the nature of your process with you exclusively for your facility.

Call (818) 998-3500 or email This email address is being protected from spambots. You need JavaScript enabled to view it. for a quote or more information.