FLUORIDE REMOVAL SYSTEMS

|

|

|

|

HF, or Hydrofluoric Acid, is a high-volume chemical that is extremely corrosive. It is miscible with water with the release of heat and an acrid, irritating odor, forming a clear, colorless liquid. HF is a significant health hazard as a liquid, even in diluted quantities. HF vapor, or Hydrogen Fluoride gas, can cause severe injury through contact, inhalation or ingestion. Free fluoride ions will destroy soft tissue and damage bones.

High fluoride levels in wastewater can be problematic for industries using hydrofluoric acid as a cleaning agent or etchant, such as the semiconductor, solar cell or metals manufacturing industries, or as a reactant or catalyst in the plastics, pharmaceutical, petroleum refining and refrigeration industries. Fluoride concentrations from these industries may range from 100 to more than 10,000 ppm in rinse waters, but discharge limits are often below 20 ppm. On site treatment is essential to economically support manufacturing facilities. For industrial applications, a Calcium Hydroxide solution (also called Milk of Lime) is frequently used to force the precipitation of fluorides as Calcium Fluoride, according to the following chemical reaction.

Ca(OH)2 + 2HF = CaF2 + 2H2O

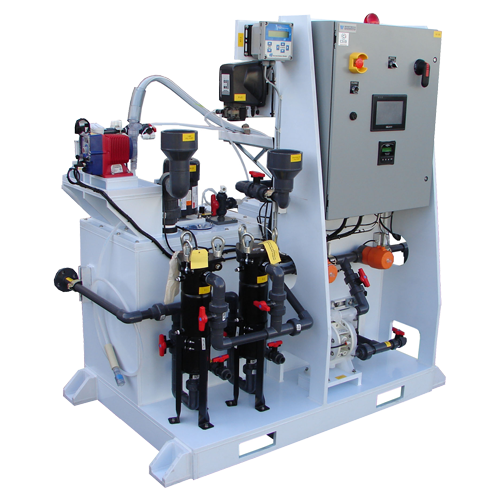

Calcium Hydroxide solution has low solubility and is corrosive, which complicates its handling and increases operating expenses, especially since it must be significantly overdosed to work effectively. Employing a combination of Calcium Hydroxide and Calcium Chloride will often provide a more economical and effective system. If there are heavy metals also present in the wastewater, such as Copper, Zinc and Chrome, then treatment with the MetFloc™ family of chemicals may be the simplest and most economical life cycle cost solution. Once the Calcium Fluoride has precipitated out of solution and treated with an appropriate coagulant, such as an anionic polymer solution, the wastewater can be effectively filtered to remove the fluorides, which are run through a filter press and bound up into a dry cake. Wastech designs Fluoride Removal Systems that are tailored to the specific needs of industrial facility operators. The key features of Wastech fluoride removal systems are:

- System design is custom tailored to actual wastewater conditions through lab analysis and process modeling

- HF resistant pH sensor elements for longer service life and reliable operation

- Fluoride specific analyzers to measure actual influent concentration and verify proper treatment prior to discharge

- Heavy duty industrial grade filter press

- Fully automated PLC-based industrial grade control system to precisely control chemical consumption with minimal operator interaction

- Lower cost to purchase, install and operate

Wastech offers standard and custom waste treatment systems for safe HF neutralization as well as Fluoride Reduction.

Fluoride wastewater treatment is increasingly important to the discharge authorities, and discharge limits of 20 ppm and lower are now common. Traditional fluoride treatment systems with calcium based chemistries can reduce fluoride discharge levels to below 20 ppm. Wastech has designed fluoride treatment systems for below 2 ppm with traditional treatment combined with secondary treatment.

Which type of system is right for your process?

Continuous Fluoride Removal Systems are extremely effective in treating large amounts of wastewater with flows higher than 15 gpm, whereas Batch systems are effective for processing smaller volumes.

For these applications, Wastech requires that a sample be sent in of the process waste fluid, where it will it will be subjected to multiple tests and analysis in our laboratory. Once the sample analysis is complete, Wastech’s team of chemical, mechanical, control and electrical engineers can recommend the optimal solution and system that is appropriate for your particular application.

Batch Fluoride Removal Systems treat the inlet wastewater in one or several "batch" tanks of various sizes.

Batch Fluoride Removal Systems treat the inlet wastewater in one or several "batch" tanks of various sizes.

The tanks are sequenced to obtain the required throughput. The batch tanks serve as the reaction tank as well as the flocculation and settling tank. The solids from the batch tanks are then filtered and disposed of appropriately. Generally, batch systems are utilized for smaller flowrates and can range up to 10,000 gallons per day.

Continuous Fluoride Removal Systems are usually used to treat larger flowrates. A continuous system utilizes reaction tanks, flocculation tank, and then a settling tank followed by filtration. The design of the filtration system depends on the inlet fluoride concentration as well as the presence of other inorganic acids that can lower the pH significantly.

Need a Custom System?

Wastech Controls and Engineering, Inc. offers custom design and engineering of state-of-the-art turnkey industrial process systems.

One of Wastech’s application engineers will discuss the nature of your process with you exclusively for your facility.

Call (818) 998-3500 or email This email address is being protected from spambots. You need JavaScript enabled to view it. for a quote or more information.