| Reduce Industrial Water Consumption Through Rainwater Recycling |

|

Wastech offers the only California Water Board-approved BACT system for rainwater recycling |

|

With water costs on the rise and drought conditions plaguing much of the United States, the need to reclaim and reuse rain/storm water has become an important part of water resource management for corporations as well as government agencies. As government regulation of industrial water usage gains momentum, “heavy users” are coming to the realization that the need to collect and re-use storm water will become increasingly necessary over the next several years as a means to reduce costs and avoid stiff fines and penalties.

“Rainwater harvesting” or “stormwater harvesting” isaccomplished by collecting rainwater runoff from facility parking lot and/or rooftop drainage systems. For industrial applications, collection and re-use of water lowers water consumption and, subsequently, cost of operation for the facility. With many government agencies charging greater and greater fees for over-use of water, recycling this water for re-use in facility processes presents a great economic incentive.

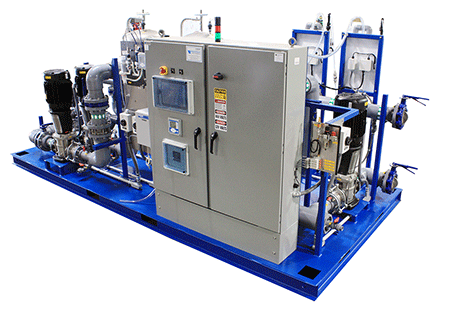

Wastech Controls & Engineering, Inc is a process systems integrator with 28 years of experience designing and manufacturing industrial wastewater treatment systems. In addition to its wide array of skid-mounted standard systems, Wastech recently installed the only California water board approved BACT system for water recycling and specializes in industrial systems for re-use of rain water. |

|

|

More About Wastech

Wastech Controls and Engineering, Inc. is a leader in process integration, engineering and manufacturing of fully automated industrial process systems. Wastech's core strengths are its people and their experience in process oriented industries. Wastech directly employs all the engineering disciplines required to thoroughly design and commission the systems it develops. Our process, mechanical, electrical and control system engineers come from diverse backgrounds with a range of experience from facility design, manufacturing and construction that enable us to tailor our systems to meet the specific needs of our clients.

Wastech's highly skilled fabricators and assemblers are competent in welding all types of plastic, assembly of piping and equipment, and installation of analytical instruments. Our panel fabrication shop is certified for UL 508A and UL 698A industrial control panels, and is unrivaled in build quality. Wastech is a certified member of the Control Systems Integrators Association (CSIA). Wastech has an unparalleled and distinguished history of customer service and support for many years following systems start and commissioning. Wastech is committed to partnering with our customers during the sales, manufacturing and after sales cycles.

|