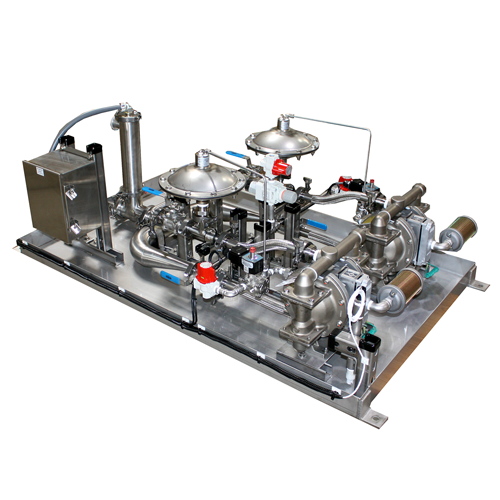

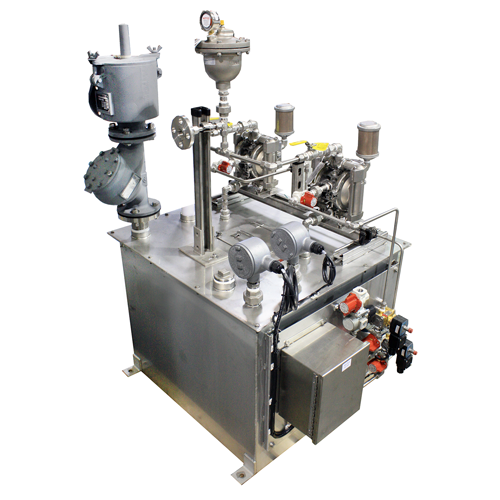

SOLVENT PUMP LIFT STATION

|

|

|

|

Wastech's Solvent Pump Lift Stations (SPLS) operate in a similar manner as air-operated pump stations, but they are specially designed to handle volatile hydrocarbon solutions. These stations feature level switches and pump solenoid valves that are designed to prevent explosions. The pump, tank, and level switches are made from stainless steel to handle solvents.

Wastech's Solvent Pump Lift Stations (SPLS) operate in a similar manner as air-operated pump stations, but they are specially designed to handle volatile hydrocarbon solutions. These stations feature level switches and pump solenoid valves that are designed to prevent explosions. The pump, tank, and level switches are made from stainless steel to handle solvents.

Specifications

- Simplex (one pump) or duplex (two pumps) configuration

- Lift station rated for Class 1 Division 1 hazardous environments

- Lift station rated for transfer and storage of Group D solvents

- Corrosion resistant 316 stainless steel tank

- Corrosion resistant 316 stainless steel piping and valves

- Intrinsically safe multipoint level switch assembly

- All pump lift stations include a high-high level switch to activate a high level alarm.

- Lift stations require Wastech industrial IAPCP control panels (or equivalent)

Standard Features

- Fabricated 316 stainless steel tank (5, 15, 30, 60, and 100 gallon tanks standard, custom sizes available)

- 316 stainless steel lid

- 316 stainless steel piping and valves

- One or two pumps—Air operated 316 stainless steel ATEX-rated double-diaphragm style (Teflon Diaphragm)

- 2” FNPT top mount inlet connection (1” for 5 gallon tank)

- 2” FNPT top mount vent connection (1” for 5 gallon tank)

- Hatch for maintenance access

- 316 stainless steel intrinsically safe multipoint float level switch assembly

- Seismic tie-downs

- Grounding lug

Optional Features

- Fabricated stainless steel double containment tank with float leak switch

- 6’ pre-wired flex cable to connect to remote control panel

- Side inlet connection

- Pressure relief valve downstream of the pumps to prevent system piping over pressure

- Pulsation dampener on discharge line (simplex) or on common discharge line (duplex)

- Enclosures and fire rated cabinets

Have questions about ordering a custom system?

One of Wastech’s application engineers will discuss the nature of your process with you exclusively for your facility.

Call (818) 998-3500 or email This email address is being protected from spambots. You need JavaScript enabled to view it. for a quote or more information.