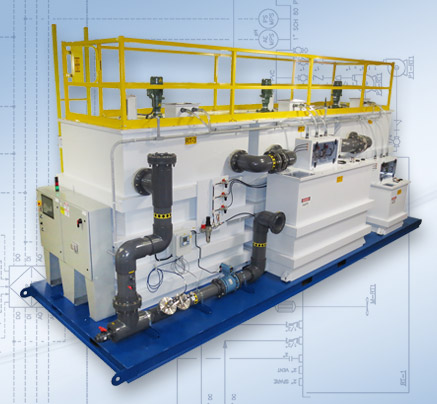

pH ADJUSTMENT SYSTEMS

Wastech Controls & Engineering, Inc. pH adjustment systems treat wastewater by neutralizing its pH, typically to a range between 6 and 9. Wastech's continuous, batch and custom series of pH adjustment systems treat small to large flows of acidic or basic wastewater.

Standard systems are available with design capacities between 100 and 400 gallons per minute. Custom systems are available with design capacities of up to 1000 gpm

Wastech employs a staff of degreed chemical, mechanical and controls engineers to provide design and support for any industrial process or wastewater application.

| LABORATORY SYSTEMS | INDUSTRIAL SYSTEMS | |

| CONTINUOUS SYSTEMS |

|

|

| BATCH SYSTEMS |

|

|

| CONCENTRATED SYSTEMS |

|

|

pH Adjustment

By definition, pH is the measure of free hydrogen activity in water. In more practical terms, although not technically correct in every case, pH is the measure of how acidic or basic a substance is. Measured on a scale of 0-14, solutions with a pH of less than 7 are considered acids while those with a pH greater than 7 are bases. At Wastech Controls & Engineering, Inc., you'll find a number of pH Adjustment Systems, as well as a wide variety of additional industrial wastewater treatment systems.

Wastech engineers and manufactures batch pH neutralization systems in both industrial and laboratory configurations that treat intermittent flows of acidic or alkaline wastewater for industrial applications. These systems treat wastewater by adjusting the pH to a neutral range, typically between 6 and 9, before discharging the water to the public sewer. For large flows, Wastech designs continuous pH adjustment systems, also available in industrial or laboratory models that can provide pH adjustment using single stage, two stage, and three stage treatment systems. This series of pH neutralization systems can be skid mounted for ease of installation and customized depending on customer needs and space constraints.

Reliability, automation, and great process performance are essential at all times, even in the presence of strong acids or caustic surges. You will not find pH neutralization or pH adjustment processes using better components or as many high-end features as the ones offered standard on a Wastech pH system.

LabDELTA® pH Adjustment Series

The LabDELTA® Laboratory pH Adjustment System offers solutions for the most common types of laboratory wastes by neutralizing acidic or caustic wastewater. Each pH adjustment system provided by Wastech is fully automated for on-site treatment as an economical alternative to waste collection and off-site disposal. The LabDELTA® series is available in the following configurations:

- LabDELTA® Plus - A skid-mounted pH adjustment system for neutralizing small-volume laboratory process wastewater and designed for continuous flows up to 3 gpm. This continuous system incorporates two active treatment stages along with effluent pH monitoring to ensure that the treated wastewater will be safe to discharge to the public sewer line.

- LabDELTA® Batch – A skid-mounted pH adjustment system that is designed for neutralizing small-volume laboratory process wastewater. This batch system includes a 20 gallon holding tank that stores wastewater before being transferred to a 10 gallon reaction tank. Batch systems use one active treatment stage to ensure that the wastewater will be neutralized to the required discharge pH level before entering the sewer line.

- LabDELTA® Concentrated – A skid-mounted system designed for neutralizing small volumes of concentrated laboratory wastewater. This system includes holding tanks for storing both acidic and caustic wastewater. The wastes are alternately added in small increments to a reaction tank containing a heel of water. Once level is made in the reaction tank and the wastewater is neutralized it is discharged to the sewer. If a waste is depleted during a treatment cycle, the system automatically switches to using chemical reagents for pH neutralization.

ProDELTA™ pH Adjustment Series

The ProDELTA™ Continuous pH Adjustment System is an industrial pH adjustment system that offers both batch and continuous solutions for applications that produce a high volume of acidic or basic process wastewater. Like its smaller laboratory counterpart, the ProDELTA™ series is compact and fully automated through a centralized control panel with HMI annd PLC-based control. The ProDELTA™ series is available in the following configurations:

- ProDELTA™ Plus – A skid-mounted, continuous pH adjustment system from Wastech designed for neutralizing process wastewater. Continuous systems use one active treatment stage for pH range 3 - 11, or two active treatment stages for pH range 2-12 along with effluent pH monitoring to ensure that the wastewater will be neutralized to the required discharge pH before entering the sewer line. Configurations are available for flowrates from 10 to 400 gallons per minute.

- ProDELTA™ Batch – A compact skid-mounted pH adjustment system designed for neutralizing process wastewater. Batch systems include an optional holding tank that stores wastewater before being transferred to the reaction tank. Batch systems use one active treatment stage along with effluent pH monitoring to ensure that the wastewater will be neutralized to the required discharge pH before entering the sewer line. The ProDELTA™ Batch treats pH range 2-12 and is available in 50, 100, 250, 500 and 1000 gallon models are available.

- ProDELTA™ Concentrated – a compact skid-mounted pH adjustment system designed for neutralizing concentrated industrial wastewater. These systems include holding tanks for storing both acidic and caustic wastewater. The wastes are alternately added in small increments to a reaction tank containing a heel of water. Once level is made in the reaction tank and the wastewater is neutralized it is discharged to the sewer. If a waste is depleted during a treatment cycle, the system automatically switches to using chemical reagents for pH neutralization. Available in 50 and 100 gallon batch configurations.

Custom pH Adjustment Systems

Many pH neutralization applications can be accomplished using pre-designed, standard products like the LabDELTA® or ProDELTA™ line of systems, but most applications require some level of customization. Wastech employs a full engineering staff of chemical, electrical, mechanical, and control engineers giving us the power to design a complete solution for any application. For a complete list of customizable features, click here.