Neutralizing Strong Acid with LabDELTA™

Strong acid, concentrated acid, superacids such as Oleum or Chlorosulfonic Acid, require a special neutralization strategy. With these chemicals, operator or technician safety is a primary concern. Automating the neutralization process with Wastech's LabDELTA™ systems takes the operator out of harm's way.

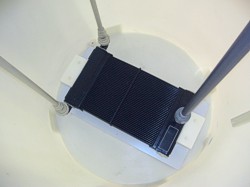

Normally the water volume itself can act as a heat sink to dissipate the heat. In extreme cases, a heat exchanger made of PVDF or PP will be installed in the reaction tank using factory supplied chilled water. High temperature materials (CPVC, PP or Teflon) for piping, metering pumps and tanks may be required. Stainless steel mixer shafts may need to be coated in Teflon. |

|

|

|

In less severe cases, the reaction will be slowed to allow heat to dissipate by slowly adding the waste to the reaction tank or diluting the chemicals by adding the waste slowly to a large water volume. Regardless, the temperature will be automatically monitored with an alarm and a shutoff of the chemicals in the alarm mode. Larger tank volumes, double containment, equalization or holding tanks, longer reaction times and responsive controls are all considered in the engineering of a LabDELTA™ solution. |

For Assistance with Strong Acid NeutralizationCall us at 818-998-3500 for a telephone consultation, engineering assistance, and a quotation. Using WebEX online teleconferencing, we can define the requirments, show examples of the hardware and other installations, and customize a LabDELTA™ strong acid neutralization solution.

|