Automation Machinery

We were told, "Manual inspection is impossible with our faster line. How can we automatically inspect and laser mark in one pass" The customer has several high-speed lines where products needed an FDA lot code and visual inspection before the filling station. Wastech Controls was asked to design and build two inspection stations. Technical challenges included the ability to inspect multiple container sizes and materials, to read and properly illuminate reflective round shapes, and to acquire and rotate each container 360º during inspection, to laser mark each container with a lot code, and accept or reject as required. Wastech's solution included high-speed material handling, motion control, machine vision, a diode-pumped YAG laser marking system, color touch-screen HMI, data acquisition, and VFD motor control. |

|

|

|

Automatic material handling equipment |

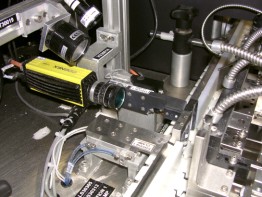

Machine vision inspection system |

|

Wastech engineers designed these machines and wrote the control software to integrate material handling, laser marking, and machine vision inspection. Software included Visual Basic / C++ program development and PLC programming to synchronize high-speed marking and inspection operations. |