FLUORIDE WASTEWATER TREATMENT (FWT)ALSO KNOWN AS HF NEUTRALIZATION OR FLUORIDE REDUCTIONA white paper by Wastech Controls & Engineering, Inc. HF, or Hydrofluoric Acid, is a high-volume chemical that is extremely corrosive. It is miscible with water with the release of heat and an acrid, irritating odor, forming a clear, colorless liquid. HF is a significant health hazard as a liquid, even in diluted quantities. HF vapor, or Hydrogen Fluoride gas, can cause severe injury through contact, inhalation or ingestion. Free fluoride ions will destroy soft tissue and damage bones. One of the more common properties of HF is that it dissolves glass. Common plastics such as polypropylene, PVC, and polyethylene are compatible with HF. Before plastics, HF used to be stored in glass bottles coated with wax. Because HF will dissolve glass, larger waste treatment vessels that might typically be fiberglass will have to be lined, which makes the vessel considerably more expensive. Plastic components are preferred for all contact with HF. HF is used in several industries in applications such as a catalyst for the petroleum industry, as an ingredient in common commercial cleaners to remove rust or spots, as an additive to rocket propellants, as a stripper to etch away silicone dioxide in semiconductor wafer production, as a cleaner to etch glass, quartz products or chrome, as a metal cleaner, as a pickling agent, and for various purposes in laboratories. Typical concentrations range up to 49%. Untreated fluoride concentrations in wastewater typically seen are in the range of a few hundred ppm up to several thousand ppm. Wastech standard systems can treat these levels of fluoride in wastewater to below required discharge limits. Custom systems can also be designed to treat higher percent-type concentrations. Wastech offers standard and custom waste treatment systems for safe HF neutralization as well as Fluoride Reduction. Fluoride wastewater treatment is increasingly important to the discharge authorities, and discharge limits of 20 ppm and lower are now common. Traditional fluoride treatment systems with calcium based chemistries can reduce fluoride discharge levels to below 20 ppm. Wastech has designed fluoride treatment systems for below 2ppm with traditional treatment combined with secondary treatment. HF is considered a weak acid, compared to common strong acids such as HCl (hydrochloric acid), HNO3 (nitric acid) or H2SO4(sulfuric acid). The fact that HF is a weak acid means the pH can still be relatively high (in the range of 2.5) even though there is the presence of percent concentrations of the acid. Strong acids such as HCL and HNO3 require a very small percentage of acid to have a very low pH. This is important when specifying a neutralization system for HF since the higher pH can deceive one into thinking there is not that much HF in the water when in fact the concentration may be quite high. Proper design of the fluoride treatment system requires knowledge of the inlet pH to the system as well as the inlet fluoride concentration. The removal of fluoride requires that the hydrofluoric acid (HF) be converted to calcium fluoride (CaF2) which is insoluble. Calcium fluoride is a relatively insoluble salt and therefore the low fluoride discharge limit is obtainable because calcium fluoride solubility in water is very low. The calcium fluoride will precipitate and then can be filtered. Calcium fluoride solubility also depends on pH so proper pH control is also required. The design of the waste treatment system depends on the form of the "fluoride" in the inlet water. For example a traditional pH neutralization system utilizing sodium hydroxide will convert the HF to sodium fluoride which is highly soluble and hence will not precipitate and therefore cannot be filtered. Removal of fluorides will require several different treatment steps which include: conversion of the soluble fluoride to insoluble calcium fluoride, flocculation of the calcium fluoride to obtain larger particles for settling, settling, filtration, and sometimes final pH readjustment. The fluoride treatment system will increase the pH of the waste water so sometimes it is possible to utilize the fluoride treatment system instead of the traditional pH neutralization system for acidic waste. If final pH adjustment is desired, then the fluoride treatment system will be required upstream of the pH neutralization system. Fluoride treatment systems can be either batch or continuous. For a batch system the inlet wastewater is treated in one or several "batch" tanks of various sizes. The tanks are sequenced to obtain the required throughput. The batch tanks serve as the reaction tank as well as the flocculation and settling tank. The solids from the batch tanks are then filtered and disposed of appropriately. Generally batch systems are utilized for smaller flowrates. Larger flowrates are usually treated in a continuous treatment system. A continuous system utilizes reaction tanks, flocculation tank, and then a settling tank followed by filtration. The design of the filtration system depends on the inlet fluoride concentration as well as the presence of other inorganic acids that can lower the pH significantly. Figure 1 shows a typical large batch fluoride treatment system with a filter press for filtration and post treatment neutralization.

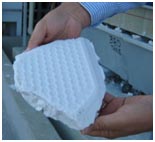

The choice of chemistry chosen for the conversion of HF to calcium fluoride will depend on the inlet pH to the system as well as the fluoride content. Generally calcium chloride, calcium hydroxide and sodium hydroxide can be used to both raise the pH as well as convert the HF to calcium fluoride. A flocculent is also required for proper filtration and settling. Calcium hydroxide is a strong base so in some instances both calcium chloride and calcium hydroxide may be required. Calcium hydroxide is a slurry so the system must be designed to properly handle a slurry. Wastech has many years experience with this type of application and our system design generally take this factor into account. The choice of chemistry will also affect the ability of the calcium fluoride to be filtered. Any calcium fluoride that passes through the filter will be considered discharge fluoride content so proper filtration is critical. Filtration method will depend on the inlet fluoride concentration. Lower inlet concentrations may allow the use of filter bags. Larger fluoride concentrations will require the use of a filter press. If the system is designed properly the filter cake from the filter press will be a dry white solid that can readily be disposed of. Wastech systems are designed for optimum choice of chemistry for the application to produce a dry calcium fluoride cake. Figure 2 below shows a typical dry cake from a properly designed system.

Wastech fluoride treatment systems are completely automated and are PLC controlled. They are generally designed with remote system monitoring with various communication protocols depending on customer preference. Discharge fluorides are monitored continuously, with an industrial total fluoride analyzer using ion-selective electrodes. Wastech has been a waste treatment system designer and process integrator for 25+ years and our process designers and controls engineers can meet virtually any design criteria for interface with a customer's building management system. To minimize installation cost, Wastech designs systems as much as possible as skid-mounted equipment. Wastech is also a fully staffed engineering company and will provide the complete system design including Process and Instrumentation diagrams, mechanical drawings, electrical panel and wiring diagrams, electrical and mechanical bills of materials and process controls. Wastech designs all their process controls in-house and does not out-source any aspect of the project, ensuring complete design to startup continuity of the system. |