| How to Choose a pH Adjustment System |

|

Many industrial processes produce wastewater that is either too acidic or too alkaline to be discharged into the public sewer. In such cases, a low cost, reliable pH adjustment solution like the fully automated, skid mounted systems offered by Wastech Controls & Engineering could bring the solution to your doorstep. Wastech's pre-packaged pH Adjustment Systems treat a wide variety of industrial waste streams and are configured at the factory to neutralize and automatically adjust the pH of your wastewater, greatly reducing labor costs, eliminating accidents and potential illegal discharge violations. Simply put, your system is engineered to pump, measure, treat, neutralize and discharge your wastewater so you have peace of mind.

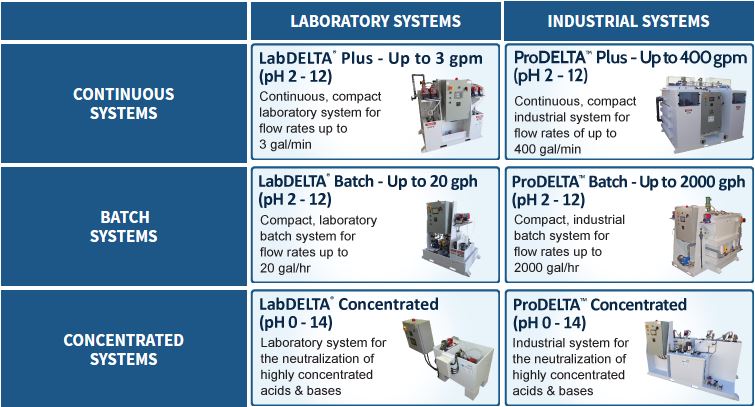

The first step is deciding which pH adjustment system you need for your process. A multitude of customizable options coupled with the fact that no two wastewater streams are exactly alike can make the selection process overwhelming, even for those with manufacturing experience. Wastech has simplified this process with its new pH Adjustment Matrix. This matrix was designed by Wastech Application Engineers to assist you in the selection process and to provide you with general specifications on the system you will need. |

|

|

Continuous pH Adjustment Systems Wastech's Continuous series of pH neutralization systems are designed to treat continuous flows of wastewater. A continuous design is recommended for higher flow rates (10-400+ GPM). Wastech's standard continuous pH systems are 2-stage systems with 2 reaction tanks for active pH adjustment followed by a third monitoring tank to ensure the exiting wastewater is within dischargeable pH limits. Each reaction tank is equipped with a mixer to constantly agitate the wastewater while metering pumps inject neutralizing chemicals directly into the tanks. The 2-stage design offers redundancy, allowing a single tank to handle pH adjustment if the other were to encounter a fault condition or be taken offline for maintenance purposes.

|

|

|

Batch pH Adjustment Systems

Wastech's Batch series of pH neutralization systems are designed to treat wastewater in batches. A batch design is recommended for relatively low (10-20 GPM), intermittent flows. Wastewater enters a holding tank where a specific volume is allowed to accumulate before being transferred to a reaction tank. In the reaction tank a mixer is used to constantly agitate the wastewater while neutralizing chemicals are added to adjust the pH to within dischargeable limits. Once the desired pH is attained, the system discharges the neutralized wastewater to the sewer.

|

|

Concentrated Systems

Wastech's Concentrated Systems, also available in batch or continuous configurations, are designed to neutralize highly-concentrated wastewater streams that are either highly acidic or highly alkaline. Both types of systems automatically and safely treat process flows with pH of 0 - 14. |

More About Wastech

Wastech Controls and Engineering, Inc. is a leader in process integration, engineering and manufacturing of fully automated industrial process systems. Wastech's core strengths are its people and their experience in process oriented industries. Wastech directly employs all the engineering disciplines required to thoroughly design and commission the systems it develops. Our process, mechanical, electrical and control system engineers come from diverse backgrounds with a range of experience from facility design, manufacturing and construction that enable us to tailor our systems to meet the specific needs of our clients.

Wastech's highly skilled fabricators and assemblers are competent in welding all types of plastic, assembly of piping and equipment, and installation of analytical instruments. Our panel fabrication shop is certified for UL 508A and UL 698A industrial control panels, and is unrivaled in build quality. Wastech is a certified member of the Control Systems Integrators Association (CSIA). Wastech has an unparalleled and distinguished history of customer service and support for many years following systems start and commissioning. Wastech is committed to partnering with our customers during the sales, manufacturing and after sales cycles.

|