Custom Chemical Dispense Systems from Wastech

|

|

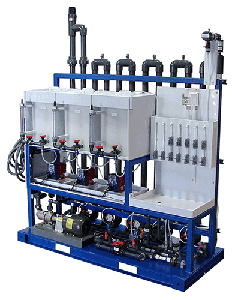

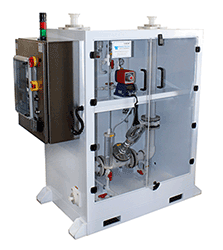

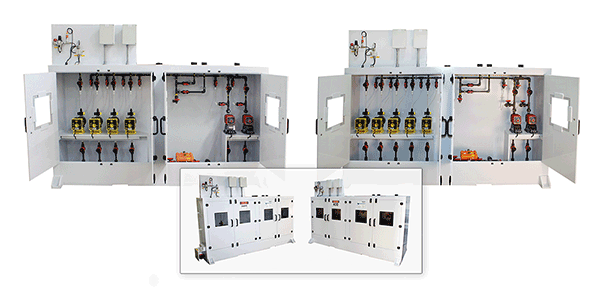

For processes that require precise and complex chemical dispense solutions, Wastech's large in house team of engineers has the experience and skill set required to design and manufacture a fully automated packaged solution tailored specifically to your unique application.

Standard System Features

Optional System Features

|

|

|

System ExamplesSulfuric Acid Chemical Dispense System:

Customer wanted a safe and effective method of injecting 93% sulfuric acid into an air stripper feed stream to reduce the negative effects of scaling and the excessive maintenance hours produced. |

More About Wastech

Wastech Controls and Engineering, Inc. is a leader in process integration, engineering and manufacturing of fully automated industrial process systems. Wastech's core strengths are its people and their experience in process oriented industries. Wastech directly employs all the engineering disciplines required to thoroughly design and commission the systems it develops. Our process, mechanical, electrical and control system engineers come from diverse backgrounds with a range of experience from facility design, manufacturing and construction that enable us to tailor our systems to meet the specific needs of our clients.

Wastech's highly skilled fabricators and assemblers are competent in welding all types of plastic, assembly of piping and equipment, and installation of analytical instruments. Our panel fabrication shop is certified for UL 508A and UL 698A industrial control panels, and is unrivaled in build quality. Wastech is a certified member of the Control Systems Integrators Association (CSIA). Wastech has an unparalleled and distinguished history of customer service and support for many years following systems start and commissioning. Wastech is committed to partnering with our customers during the sales, manufacturing and after sales cycles.

|